What Substance Did Portuguese Explorers Refer to as White Gold? Art History

| Porcelain | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Chinese | 瓷 | ||||||||||||||||||

| |||||||||||||||||||

Porcelain () is a ceramic material made by heating substances, by and large including materials such as kaolinite, in a kiln to temperatures between i,200 and one,400 °C (2,200 and 2,600 °F). The forcefulness, and translucence of porcelain, relative to other types of pottery, arises mainly from vitrification and formation of the mineral mullite within the torso at these high temperatures. Though definitions vary, porcelain can be divided into three main categories: hard-paste, soft-paste and bone communist china. The category that an object belongs to depends on the composition of the paste used to brand the body of the porcelain object and the firing atmospheric condition.

Porcelain slowly evolved in China and was finally achieved (depending on the definition used) at some betoken about ii,000 to 1,200 years ago, then slowly spread to other East Asian countries, and so to Europe and eventually to the residual of the world. Its manufacturing process is more than enervating than that for earthenware and stoneware, the two other primary types of pottery, and information technology has usually been regarded equally the nearly prestigious type of pottery for its delicacy, strength, and its white color. It combines well with both glazes and paint, and tin can exist modelled very well, allowing a huge range of decorative treatments in tableware, vessels and figurines. Information technology also has many uses in engineering and industry.

The European name, porcelain in English language, comes from the old Italian porcellana (cowrie beat out) because of its resemblance to the surface of the crush.[1] Porcelain is besides referred to equally china or fine china in some English-speaking countries, every bit it was first seen in imports from China.[2] Backdrop associated with porcelain include low permeability and elasticity; considerable strength, hardness, whiteness, translucency and resonance; and a loftier resistance to corrosive chemicals and thermal shock.

Flower centrepiece, 18th century, Espana

Porcelain has been described equally beingness "completely vitrified, hard, impermeable (even earlier glazing), white or artificially coloured, translucent (except when of considerable thickness), and resonant".[3] However, the term "porcelain" lacks a universal definition and has "been applied in an unsystematic mode to substances of diverse kinds which accept only certain surface-qualities in common".[four]

Traditionally, East asia but classifies pottery into low-fired wares (earthenware) and high-fired wares (frequently translated equally porcelain), the latter too including what Europeans telephone call stoneware, which is high-fired but non generally white or translucent. Terms such as "proto-porcelain", "porcellaneous" or "nigh-porcelain" may be used in cases where the ceramic body approaches whiteness and translucency.[5]

Types [edit]

Chinese Imperial Dish with Flowering Prunus, Famille Rose overglaze enamel, between 1723 and 1735

Sit-in of the translucent quality of porcelain

Hard paste [edit]

Hard-paste porcelain was invented in China, and it was as well used in Japanese porcelain, and most of the finest quality porcelain wares are in this material. The earliest European porcelains were produced at the Meissen factory in the early on 18th century; they were formed from a paste composed of kaolin and alabaster and fired at temperatures upward to ane,400 °C (2,552 °F) in a woods-fired kiln, producing a porcelain of great hardness, translucency, and strength.[6] Afterwards, the composition of the Meissen hard paste was changed and the alabaster was replaced by feldspar and quartz, allowing the pieces to be fired at lower temperatures. Kaolinite, feldspar and quartz (or other forms of silica) keep to constitute the basic ingredients for about continental European hard-paste porcelains.

Soft paste [edit]

Soft-paste porcelains appointment back from early attempts past European potters to replicate Chinese porcelain by using mixtures of clay and frit. Soapstone and lime are known to have been included in these compositions. These wares were not yet actual porcelain wares every bit they were neither hard nor vitrified by firing kaolin clay at high temperatures. Equally these early formulations suffered from high pyroplastic deformation, or slumping in the kiln at loftier temperatures, they were uneconomic to produce and of low quality.

Formulations were later adult based on kaolin with quartz, feldspars, nepheline syenite or other feldspathic rocks. These are technically superior, and continue to be produced. Soft-paste porcelains are fired at lower temperatures than hard-paste porcelain, therefore these wares are generally less difficult than hard-paste porcelains.[7] [eight]

Bone mainland china [edit]

Although originally adult in England in 1748[9] to compete with imported porcelain, os china is now made worldwide, including China. The English had read the letters of Jesuit missionary François Xavier d'Entrecolles, which described Chinese porcelain manufacturing secrets in item.[10] One author has speculated that a misunderstanding of the text could mayhap accept been responsible for the commencement attempts to use bone-ash as an ingredient of English porcelain,[10] although this is not supported by modern researchers and historians.[xi] [12] [13] [xiv] [xv]

Traditionally, English os china was fabricated from two parts of bone ash, one role of kaolin and one part china rock, although the latter has largely been replaced past feldspars from non-UK sources.[sixteen] Merely for case Royal Crown Derby still uses 50% os ash in the 21st century.

Materials [edit]

Kaolin is the primary textile from which porcelain is fabricated, even though clay minerals might account for only a small proportion of the whole. The word paste is an old term for both unfired and fired materials. A more mutual terminology for the unfired material is "body"; for example, when buying materials a potter might lodge an corporeality of porcelain trunk from a vendor.

The composition of porcelain is highly variable, but the clay mineral kaolinite is often a raw material. Other raw materials can include feldspar, ball clay, glass, bone ash, steatite, quartz, petuntse and alabaster.

The clays used are often described as being long or brusk, depending on their plasticity. Long clays are cohesive (pasty) and take high plasticity; short clays are less cohesive and have lower plasticity. In soil mechanics, plasticity is adamant by measuring the increase in content of water required to modify a dirt from a solid state bordering on the plastic, to a plastic state bordering on the liquid, though the term is too used less formally to describe the ease with which a clay may be worked.

Clays used for porcelain are generally of lower plasticity and are shorter than many other pottery clays. They moisture very apace, meaning that small changes in the content of water can produce big changes in workability. Thus, the range of water content inside which these clays can be worked is very narrow and consequently must be carefully controlled.

Production [edit]

Forming [edit]

Porcelain can exist made using all the shaping techniques for pottery. It was originally typically made on the potter's wheel, though moulds were also used from early on. Slipcasting has been the most mutual commercial method in recent times.

Glazing [edit]

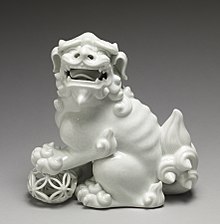

Biscuit porcelain is unglazed porcelain treated equally a finished product, generally for figures and sculpture. Unlike their lower-fired counterparts, porcelain wares do not need glazing to render them impermeable to liquids and for the nearly part are glazed for decorative purposes and to make them resistant to dirt and staining. Many types of glaze, such as the iron-containing coat used on the celadon wares of Longquan, were designed specifically for their striking effects on porcelain.

Decoration [edit]

Porcelain ofttimes receives underglaze decoration using pigments that include cobalt oxide and copper, or overglaze enamels, allowing a wider range of colours. Similar many before wares, modern porcelains are often biscuit-fired at around 1,000 °C (1,830 °F), coated with coat and then sent for a 2nd glaze-firing at a temperature of well-nigh ane,300 °C (two,370 °F) or greater. Some other early method is "in one case-fired", where the glaze is applied to the unfired body and the 2 fired together in a unmarried performance.

Firing [edit]

In this process, "light-green" (unfired) ceramic wares are heated to high temperatures in a kiln to permanently set their shapes, vitrify the body and the coat. Porcelain is fired at a higher temperature than earthenware so that the trunk can vitrify and become non-porous. Many types of porcelain in the past have been fired twice or even three times, to allow decoration using less robust pigments in overglaze enamel.

History [edit]

Chinese porcelain [edit]

Porcelain was invented in Communist china over a centuries-long development menstruation beginning with "proto-porcelain" wares dating from the Shang dynasty (1600–1046 B.C.Eastward). Past the fourth dimension of the Eastern Han dynasty (CE 25–220) these early glazed ceramic wares had adult into porcelain, which Chinese defined equally loftier-fired ware.[17] [18] By the belatedly Sui dynasty (581–618 CE) and early Tang dynasty (618–907 CE), the now-standard requirements of whiteness and translucency had been accomplished,[xix] in types such every bit Ding ware. The wares were already exported to the Islamic world, where they were highly prized.[18] [twenty]

Eventually, porcelain and the expertise required to create information technology began to spread into other areas of Eastern asia. During the Song dynasty (960–1279 Advertising), artistry and product had reached new heights. The manufacture of porcelain became highly organised, and the dragon kilns excavated from this catamenia could fire equally many as 25,000 pieces at a fourth dimension,[21] and over 100,000 by the cease of the menstruation.[22] While Xing ware is regarded every bit among the greatest of the Tang dynasty porcelain, Ding ware became the premier porcelain of the Vocal dynasty.[23] By the Ming dynasty, production of the finest wares for the court was concentrated in a single city, and Jingdezhen porcelain, originally owned past the majestic government, remains the centre of Chinese porcelain product.

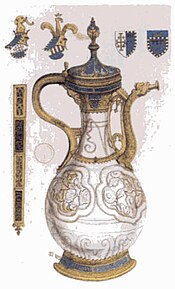

Past the time of the Ming dynasty (1368–1644 AD), porcelain wares were beingness exported to Asia and Europe. Some of the virtually well-known Chinese porcelain art styles arrived in Europe during this era, such equally the coveted "blue-and-white" wares.[24] The Ming dynasty controlled much of the porcelain trade, which was expanded to Asia, Africa and Europe via the Silk Road. In 1517, Portuguese merchants began direct trade by bounding main with the Ming dynasty, and in 1598, Dutch merchants followed.[xx]

Some porcelains were more than highly valued than others in imperial China. The most valued types can be identified by their association with the court, either as tribute offerings, or as products of kilns under majestic supervision.[25] Since the Yuan dynasty, the largest and best center of production has fabricated Jingdezhen porcelain. During the Ming dynasty, Jingdezhen porcelain become a source of imperial pride. The Yongle emperor erected a white porcelain brick-faced pagoda at Nanjing, and an exceptionally smoothly glazed type of white porcelain is peculiar to his reign. Jingdezhen porcelain's fame came to a peak during the Qing dynasty.

Japanese porcelain [edit]

Although the Japanese elite were keen importers of Chinese porcelain from early on, they were not able to make their own until the inflow of Korean potters that were taken captive during the Japanese invasions of Korea (1592–1598). They brought an improved type of kiln, and i of them spotted a source of porcelain dirt almost Arita, and shortly several kilns had started in the region. At first their wares were similar to the cheaper and cruder Chinese porcelains with underglaze bluish decoration that were already widely sold in Japan; this style was to continue for cheaper everyday wares until the 20th century.[26]

Exports to Europe began effectually 1660, through the Chinese and the Dutch Due east India Visitor, the only Europeans immune a trading presence. Chinese exports had been seriously disrupted by civil wars every bit the Ming dynasty cruel apart, and the Japanese exports increased apace to fill the gap. At showtime the wares used European shapes and more often than not Chinese decoration, as the Chinese had done, but gradually original Japanese styles developed.

Nabeshima ware was produced in kilns owned by the families of feudal lords, and were decorated in the Japanese tradition, much of it related to textile blueprint. This was not initially exported, just used for gifts to other aristocratic families. Imari ware and Kakiemon are wide terms for styles of export porcelain with overglaze "enamelled" decoration begun in the early on period, both with many sub-types.[27]

A groovy range of styles and manufacturing centres were in use by the start of the 19th century, and equally Japan opened to merchandise in the 2nd half, exports expanded hugely and quality generally declined. Much traditional porcelain continues to replicate older methods of production and styles, and in that location are several mod industrial manufacturers.[28] Past the early 1900s, Filipino porcelain artisans working in Japanese porcelain centres for much of their lives, later on on introduced the craft into the native population in the Philippines,[29] although oral literature from Cebu in the cardinal Philippines accept noted that porcelain were already being produced by the natives locally during the time of Cebu's early rulers, prior to the arrival of colonizers in the 16th century.[30]

European porcelain [edit]

These exported Chinese porcelains were held in such great esteem in Europe that in English china became a ordinarily–used synonym for the Italian-derived porcelain. The outset mention of porcelain in Europe is in Il Milione by Marco Polo in the 13th century.[31] Autonomously from copying Chinese porcelain in faience (tin glazed earthenware), the soft-paste Medici porcelain in 16th-century Florence was the first real European effort to reproduce information technology, with little success.

Early in the 16th century, Portuguese traders returned dwelling house with samples of kaolin, which they discovered in China to be essential in the production of porcelain wares. However, the Chinese techniques and composition used to industry porcelain were not yet fully understood.[21] Countless experiments to produce porcelain had unpredictable results and met with failure.[21] In the German country of Saxony, the search ended in 1708 when Ehrenfried Walther von Tschirnhaus produced a hard, white, translucent type of porcelain specimen with a combination of ingredients, including kaolin and alabaster, mined from a Saxon mine in Colditz.[32] [half dozen] Information technology was a closely guarded trade secret of the Saxon enterprise.[6] [33]

In 1712, many of the elaborate Chinese porcelain manufacturing secrets were revealed throughout Europe by the French Jesuit father Francois Xavier d'Entrecolles and soon published in the Lettres édifiantes et curieuses de Chine par des missionnaires jésuites.[34] The secrets, which d'Entrecolles read about and witnessed in Red china, were now known and began seeing use in Europe.[34]

Meissen [edit]

Von Tschirnhaus along with Johann Friedrich Böttger were employed by Augustus Ii, King of Poland and Elector of Saxony, who sponsored their work in Dresden and in the boondocks of Meissen. Tschirnhaus had a broad knowledge of science and had been involved in the European quest to perfect porcelain manufacture when, in 1705, Böttger was appointed to aid him in this task. Böttger had originally been trained equally a pharmacist; afterward he turned to alchemical research, he claimed to have known the secret of transmuting dross into gold, which attracted the attention of Augustus. Imprisoned by Augustus every bit an incentive to hasten his research, Böttger was obliged to work with other alchemists in the futile search for transmutation and was eventually assigned to assist Tschirnhaus.[32] One of the first results of the collaboration between the ii was the development of a red stoneware that resembled that of Yixing.

A workshop note records that the first specimen of hard, white and vitrified European porcelain was produced in 1708. At the fourth dimension, the research was still being supervised by Tschirnhaus; nonetheless, he died in October of that yr. It was left to Böttger to study to Augustus in March 1709 that he could brand porcelain. For this reason, credit for the European discovery of porcelain is traditionally ascribed to him rather than Tschirnhaus.[35]

The Meissen factory was established in 1710 after the development of a kiln and a coat suitable for apply with Böttger'south porcelain, which required firing at temperatures of upwardly to 1,400 °C (ii,552 °F) to attain translucence. Meissen porcelain was one time-fired, or light-green-fired. Information technology was noted for its peachy resistance to thermal shock; a visitor to the mill in Böttger'due south time reported having seen a white-hot teapot being removed from the kiln and dropped into cold h2o without damage. Although widely disbelieved this has been replicated in modern times.[36]

Russian porcelain [edit]

In 1744, the Elizabeth of Russian federation signed an agreement to establish the first porcelain mill; previously it had to exist imported. The technology of making "white gilt" was carefully subconscious by its creators. Peter the Great had tried to reveal the "big porcelain secret", and sent an agent to the Meissen factory, and finally hired a porcelain master from abroad.[37] This relied on the research of the Russian scientist Dmitry Ivanovich Vinogradov. His development of porcelain manufacturing technology was not based on secrets learned through 3rd parties, but was the result of painstaking piece of work and careful analysis. Cheers to this, past 1760, Imperial Porcelain Mill, Saint petersburg became a major European factories producing tableware, and later porcelain figurines.[38] Eventually other factories opened: Gardner porcelain, Dulyovo (1832), Kuznetsovsky porcelain, Popovsky porcelain, and Gzhel.[ citation needed ]

During the twentieth century, under Soviet governments, ceramics continued to exist a pop artform, supported by the state, with an increasingly propagandist part.[39] [40] I artist, who worked at the Baranovsky Porcelain Manufactory and at the Experimental Ceramic and Artistic Plant in Kyiv, was Oksana Zhnikrup, whose porcelain figures of the ballet and the circus were widely known.[41]

Soft paste porcelain [edit]

The pastes produced by combining dirt and powdered glass (frit) were chosen Frittenporzellan in Germany and frita in Spain. In France they were known as pâte tendre and in England equally "soft-paste".[42] They appear to accept been given this name because they practice not easily retain their shape in the moisture state, or because they tend to slump in the kiln under loftier temperature, or because the body and the coat can be easily scratched.

- France

Experiments at Rouen produced the earliest soft-paste in France, simply the first of import French soft-paste porcelain was made at the Saint-Cloud factory before 1702. Soft-paste factories were established with the Chantilly manufactory in 1730 and at Mennecy in 1750. The Vincennes porcelain mill was established in 1740, moving to larger premises at Sèvres[43] in 1756. Vincennes soft-paste was whiter and freer of imperfections than any of its French rivals, which put Vincennes/Sèvres porcelain in the leading position in France and throughout the whole of Europe in the 2nd half of the 18th century.[44]

- Italy

Doccia porcelain of Florence was founded in 1735 and remains in production, unlike Capodimonte porcelain which was moved from Naples to Madrid by its royal owner, after producing from 1743 to 1759. After a gap of 15 years Naples porcelain was produced from 1771 to 1806, specializing in Neoclassical styles. All these were very successful, with big outputs of high-quality wares. In and around Venice, Francesco Vezzi was producing hard-paste from effectually 1720 to 1735; survivals of Vezzi porcelain are very rare, only less and then than from the Hewelke factory, which simply lasted from 1758 to 1763. The soft-paste Cozzi factory fared ameliorate, lasting from 1764 to 1812. The Le Nove factory produced from well-nigh 1752 to 1773, then was revived from 1781 to 1802.[45]

- England

The showtime soft-paste in England was demonstrated by Thomas Briand to the Imperial Society in 1742 and is believed to have been based on the Saint-Deject formula. In 1749, Thomas Frye took out a patent on a porcelain containing bone ash. This was the first bone cathay, after perfected by Josiah Spode. William Cookworthy discovered deposits of kaolin in Cornwall, and his manufactory at Plymouth, established in 1768, used kaolin and communist china rock to make hard-paste porcelain with a body composition similar to that of the Chinese porcelains of the early 18th century. But the great success of English ceramics in the 18th century was based on soft-paste porcelain, and refined earthenwares such as creamware, which could compete with porcelain, and had devastated the faience industries of France and other continental countries by the end of the century. Most English porcelain from the late 18th century to the nowadays is bone mainland china.

In the twenty-five years after Briand'southward sit-in, a number of factories were founded in England to make soft-paste tableware and figures:

- Chelsea (1743)[46] [47]

- Bow (1745)[48] [49] [l]

- St James's (1748)[fifty] [51]

- Bristol porcelain (1748)

- Longton Hall (1750)[52]

- Royal Crown Derby (1750 or 1757)[53] [54]

- Royal Worcester (1751)

- Lowestoft porcelain (1757)[55]

- Wedgwood (1759)

- Spode (1767)

Other uses [edit]

Electric insulating material [edit]

Porcelain insulator for medium-high voltage

Porcelain and other ceramic materials have many applications in engineering, especially ceramic applied science. Porcelain is an splendid insulator for utilise with high voltages, especially in outdoor applications (see Insulator (electricity)#Material). Examples include: terminals for high-voltage cables, bushings of power transformers, and insulation of high-frequency antennas.

Edifice textile [edit]

Porcelain can be used as a building material, usually in the form of tiles or large rectangular panels. Modern porcelain tiles are generally produced by a number of recognised international standards and definitions.[56] [57] Manufacturers are plant across the globe[58] with Italy existence the global leader, producing over 380 million square metres in 2006.[59] Historic examples of rooms busy entirely in porcelain tiles can be plant in several European palaces including ones at Galleria Sabauda in Turin, Museo di Doccia in Sesto Fiorentino, Museo di Capodimonte in Naples, the Royal Palace of Madrid and the nearby Royal Palace of Aranjuez.[60] and the Porcelain Belfry of Nanjing.

More recent noteworthy examples include the Dakin Building in Brisbane, California, and the Gulf Edifice in Houston, Texas, which when constructed in 1929 had a 21-metre-long (69 ft) porcelain logo on its exterior.[61] A more detailed description of the history, manufacture and properties of porcelain tiles is given in the commodity "Porcelain Tile: The Revolution Is Merely Offset."[61]

Bathroom fittings [edit]

Porcelain Chamber Pots from Vienna.

Considering of its durability, inability to rust and impermeability, glazed porcelain has been in employ for personal hygiene since at least the third quarter of the 17th century. During this catamenia, porcelain bedchamber pots were commonly constitute in college-course European households, and the term "bourdaloue" was used as the proper noun for the pot.[62]

Withal bathroom tubs are not fabricated of porcelain, but of porcelain enamel on a metal base, usually of cast iron. Porcelain enamel is a marketing term used in the US, and is not porcelain but vitreous enamel.[63]

Dental porcelain [edit]

Dental porcelain is used for crowns, bridges and veneers.

Manufacturers [edit]

Porcelain wares, such as those like to these Yongle-era porcelain flasks, were often presented as trade goods during the 15th-century Chinese maritime expeditions. (British Museum)

- The Americas

- Brazil

- Germer Porcelanas Finas

- pt:Porcelana Schmidt

- United States

- Blueish Ridge

- CoorsTek, Inc.

- Franciscan

- Lenox

- Lotus Ware

- Pickard Cathay

- Brazil

- Asia

- Red china

- Ding ware

- Jingdezhen porcelain

- Iran

- Maghsoud Group of Factories, (1993–present)[64]

- Zarin Iran porcelain Industries, (1881–present)[65]

- Japan

- Hirado ware

- Kakiemon

- Nabeshima ware

- Narumi

- Noritake

- Schmid Kreglinger

- Malaysia

- Imperial Selangor

- Republic of korea

- Haengnam Chinaware

- Hankook Chinaware

- Sri Lanka

- Dankotuwa Porcelain

- Noritake Lanka Porcelain

- Imperial Fernwood Porcelain

- Taiwan

- Franz Collection

- Turkey

- Yildiz Porselen (1890–1936, 1994–present)

- Kütahya Porselen (1970–present)

- Güral Porselen (1989–present)

- Porland Porselen (1976–present)

- Istanbul Porselen (1963 – early 1990s)

- Sümerbank Porselen (1957–1994)

- United Arab Emirates

- RAK Porcelain

- Vietnam

- Minh Long I porcelain (1970–present)[66]

- Bát Tràng porcelain (1352–present)

- Red china

- Europe

- Austria

- Vienna Porcelain Manufactory, 1718–1864

- Vienna Porcelain Manufactory Augarten, 1923–nowadays

- Croatia

- Inkerpor (1953–present)

- Czechia

- Haas & Czjzek, Horní Slavkov (1792–2011)

- Thun 1794, Klášterec nad Ohří (1794–nowadays)

- Český porcelán a.s., Dubí, Eichwelder Porzellan und Ofenfabriken Bloch & Co. Böhmen (1864–present)

- Rudolf Kämpf, Nové Sedlo (Sokolov Commune) (1907–nowadays)

- Denmark

- Aluminia

- Bing & Grøndahl

- Denmark porcelain

- P. Ipsens Enke

- Kastrup Vaerk

- Kronjyden

- Porcelænshaven

- Royal Copenhagen (1775–present)

- GreenGate

- Finland

- Arabia

- France

- Saint-Cloud porcelain (1693–1766)

- Chantilly porcelain (1730–1800)

- Vincennes porcelain (1740–1756)

- Mennecy-Villeroy porcelain (1745–1765)

- Sèvres porcelain (1756–nowadays)

- Revol porcelain (1789–nowadays)

- Limoges porcelain

- Haviland porcelain

- Germany

- Electric current porcelain manufacturers in Frg

- Republic of hungary

- Hollóháza Porcelain Manufacturing plant (1777–present)

- Herend Porcelain Manufacture (1826–present)

- Zsolnay Porcelain Manufacture (1853–present)

- Italy

- Richard-Ginori 1735 Manifattura di Doccia (1735–present)[67]

- Capodimonte porcelain (1743–1759)

- Naples porcelain (1771–1806)

- Manifattura Italiana Porcellane Artistiche Fabris (1922–1972)

- Mangani SRL, Porcellane d'Arte (Florence)

- Lithuania

- Jiesia[68]

- Netherlands

- Haagsche Plateelbakkerij, Rozenburg

- Loosdrechts Porselein

- Weesp Porselein

- Norway

- Egersund porcelain

- Figgjo (1941–present)

- Herrebøe porcelain

- Porsgrund

- Stavangerflint

- Poland

- AS Ćmielów

- Fabryka Fajansu i Porcelany[69]

- Polskie Fabryki Porcelany "Ćmielów" i "Chodzież" S.A.[70]

- Kristoff Porcelana[71]

- Lubiana S.A.[72]

- Portugal

- Vista Alegre

- Sociedade Porcelanas de Alcobaça

- Costa Verde (company), located in the district of Aveiro

- Russia

- Majestic Porcelain Factory, Saint Petersburg (1744–present)

- Verbilki Porcelain (1766–present), Verbilki about Taldom

- Gzhel ceramics (1802–present), Gzhel

- Dulevo Farfor (1832–present), Likino-Dulyovo

- Espana

- Buen Retiro Royal Porcelain Factory (1760–1812)

- Real Fábrica de Sargadelos (1808–present, intermittently)

- Porvasal

- Switzerland

- Suisse Langenthal

- Sweden

- Rörstrand

- Gustavsberg porcelain

- United Kingdom

- Aynsley China (1775–present)

- Belleek (1884–nowadays)

- Bow porcelain factory (1747–1776)

- Caughley porcelain

- Chelsea porcelain manufacturing plant (c. 1745; merged with Derby in 1770)

- Coalport porcelain

- Davenport

- Goss crested china

- Liverpool porcelain

- Longton Hall porcelain

- Lowestoft Porcelain Manufacturing plant

- Mintons Ltd (1793–1968; merged with Imperial Doulton)

- Nantgarw Pottery

- New Hall porcelain

- Plymouth Porcelain

- Rockingham Pottery

- Purple Crown Derby (1750/57–present)

- Imperial Doulton (1815–2009; acquired by Fiskars)

- Royal Worcester (1751–2008; acquired past Portmeirion Pottery)

- Spode (1767–2008; acquired by Portmeirion Pottery)

- Saint James'south Manufacturing plant (or "Girl-in-a-Swing", 1750s)

- Swansea porcelain

- Vauxhall porcelain

- Wedgwood, (manufacturing plant 1759–present, porcelain 1812–1829, and modern. Caused by Fiskars)

- Austria

See also [edit]

- Blueish and white porcelain

- List of porcelain manufacturers

- Lithophane

- Sea pottery

Notes [edit]

- ^ "Porcelain, n. and adj". Oxford English Dictionary . Retrieved 18 Jun 2018.

- ^ OED, "China"; An Introduction to Pottery. 2nd edition. Rado P. Institute of Ceramic / Pergamon Press. 1988. Usage of "china" in this sense is inconsistent, & it may be used of other types of ceramics too.

- ^ Harmonized article description and coding system: explanatory notes, Volume iii, 1986, Customs Co-operation Council, U.Due south. Customs Service, U.Southward. Section of the Treasury

- ^ Definition in The Combined Classification of the European Communities defines, Burton, 1906

- ^ Valenstein, S. (1998). A handbook of Chinese ceramics Archived September 9, 2016, at the Wayback Machine, pp. 22, 59-60, 72, Metropolitan Museum of Art, New York. ISBN 9780870995149

- ^ a b c Richards, Sarah (1999). Eighteenth-century ceramic: Products for a civilised club . Manchester: Manchester University Press. pp. 23–26. ISBN978-0-7190-4465-6.

- ^ Reed, Cleota; Skoczen; Stan (1997). Syracuse Prc. Syracuse, N.Y.: Syracuse University Press. pp. 51–52. ISBN978-0-8156-0474-7. Archived from the original on 2014-01-07.

- ^ Due north. Hudson Moore (1903). The Old Mainland china Book. p. 7. ISBN978-one-4344-7727-nine. Archived from the original on 2013-05-28.

- ^ Strumpf, Faye (2000). Limoges boxes: A complete guide. Iola, WI: Krause Publications. p. 125. ISBN978-0-87341-837-9. Archived from the original on 2017-12-02.

- ^ a b Burton, William (1906). Porcelain, Its Nature, Art and Manufacture. London. pp. eighteen–19.

- ^ Science Of Early English Porcelain. Freestone I C. Sixth Conference and Exhibition of the European Ceramic Lodge. Extended Abstracts. Vol.1 Brighton, 20–24 June 1999, pg.11-17

- ^ The Special Entreatment Of Bone Communist china. Cubbon R C P.Tableware Int. eleven, (9), 30, 1981

- ^ All Near Bone China. Cubbon R C P. Tableware Int. ten, (ix), 34, 1980

- ^ Spode's Os China – Progress In Processing Without Compromise In Quality. George R T; Forbes D; Plant P. Ceram. Ind. 115, (six), 32, 1980

- ^ An Introduction To The Technology Of Pottery. Paul Rado. Establish of Ceramics & Pergamon Printing, 1988

- ^ Changes & Developments Of Not-plastic Raw Materials. Sugden A. International Ceramics Result 2 2001.

- ^ Kelun, Chen (2004). Chinese porcelain: Art, elegance, and appreciation. San Francisco: Long River Press. p. 3. ISBN978-1-59265-012-5. Archived from the original on 2013-05-28.

- ^ a b "Porcelain". Columbia Encyclopedia Sixth Edition. 2008. Archived from the original on 2009-03-02. Retrieved 2008-06-27 .

- ^ Vainker, 66

- ^ a b Te-m'un, Cheng (1984). Studies in Chinese ceramics. Hong Kong: Chinese University Printing. pp. 92–93. ISBN978-962-201-308-seven. Archived from the original on 2017-12-02.

- ^ a b c Temple, Robert K.G. (2007). The Genius of Red china: iii,000 Years of Science, Discovery, and Invention (tertiary edition). London: André Deutsch, pp. 104-5. ISBN 978-0-233-00202-vi

- ^ Kerr, Rose, Needham, Joseph, Wood, Nigel, Science and Culture in Cathay: Book 5, Chemistry and Chemic Applied science, Part 12, Ceramic Engineering, 2004, Cambridge University Press, ISBN 978-0-521-83833-7, Google books

- ^ Wood, Nigel (2011). Chinese Glazes: Their Origins, Chemistry, and Recreation. London: A. & C. Black. ISBN978-1-4081-4025-3.

- ^ Cohen, David Harris; Hess, Catherine (1993). Looking at European ceramics : a guide to technical terms. Malibu: The J. Paul Getty Museum Journal. p. 59. ISBN978-0-89236-216-5. Archived from the original on 2014-07-06.

- ^ Rawson, Jessica "Chinese Art", 2007, publisher:the British Museum Printing, London, ISBN 978-0-7141-2446-9

- ^ Smith, Harris, & Clark, 163-164; Watson, 260

- ^ Smith, Harris, & Clark, 164-165; Watson, 261

- ^ Smith, Harris, & Clark, 165; Watson, 261

- ^ De Ayala, Fernando Zobel (1961). "The Starting time Philippine Porcelain". Philippine Studies. 9 (1): 17–nineteen. JSTOR 42719652.

- ^ Ouano-Savellon, R. (2014). Philippine Quarterly of Culture and Society Vol. 42, No. 3/4: Aginid Bayok Sa Atong Tawarik: Archaic Cebuano and Historicity in a Folk Narrative. University of San Carlos Publications.

- ^ cap. CLVIII dell'edizione a cura di Fifty.F. Benedetto, 1928; cap. 153 dell'edizione a cura di V. Pizzorusso Bertolucci

- ^ a b Burns, William East. (2003). Science in the enlightenment: An encyclopedia. Santa Barbara: ABC-Clio. pp. 38–39. ISBN978-1-57607-886-0. Archived from the original on 2015-11-twenty.

- ^ Wardropper, Ian (1992). News from a radiant future: Soviet porcelain from the collection of Craig H. and Kay A. Tuber. Chicago: Art Institute of Chicago. ISBN978-0-86559-106-half-dozen. Archived from the original on 2017-12-02.

- ^ a b • Baghdiantz McAbe, Ina (2008). Orientalism in Early Mod French republic. Oxford: Berg Publishing, p. 220. ISBN 978-1-84520-374-0

• Finley, Robert (2010). The pilgrim art. Cultures of porcelain in world history. University of California Printing, p. 18. ISBN 978-0-520-24468-9

• Kerr, R. & Wood, N. (2004). Joseph Needham : Science and Culture in Cathay, Volume 5 Chemistry and Chemical Technology : Part 12 Ceramic Technology Archived August one, 2016, at the Wayback Machine. Cambridge University Press, p. 36-7. ISBN 0-521-83833-9

• Zhang, Xiping (2006). Following the steps of Matteo Ricci to China. Beijing: China Intercontinental Press. p. 168. ISBN978-seven-5085-0982-2. Archived from the original on 2013-05-28.

• Burton, William (1906). Porcelain, Its Nature, Art and Manufacture. London. pp. 47–48. - ^ Gleeson, Janet. The Arcanum, an authentic historic novel on the greed, obsession, murder and expose that led to the creation of Meissen porcelain. Bantam Books, London, 1998.

- ^ BBC4 How it works: Ep 3. Ceramics how they piece of work 16 Apr 2012

- ^ History of Russian inventions. Porcelain. (In Russian).

- ^ History of Russian porcelain: from its origins to the present 24-hour interval.

- ^ Lobanov-Rostovsky, Nina (1989). "Soviet Propaganda Porcelain". The Journal of Decorative and Propaganda Arts. xi: 126–141. ISSN 0888-7314.

- ^ Crichton-Miller, Emma. "The tale of Russia's revolutionary ceramics | Weblog | Royal University of Arts". www.royalacademy.org.u.k. . Retrieved 2022-03-03 .

- ^ "Porcelain Pop Art by Oksana Zhnikrup". Ukrainian Art Library . Retrieved 2022-03-02 .

- ^ Beloved, W.B., European Ceramic Art, Faber and Faber, 1952, p.533

- ^ Munger, Jeffrey (Oct 2004). "Sèvres Porcelain in the Nineteenth Century Archived September 3, 2016, at the Wayback Machine". In Heilbrunn Timeline of Art History. New York: The Metropolitan Museum of Fine art. Retrieved 31 Oct 2011

- ^ Metropolitan Museum of Art Archived May 8, 2016, at the Wayback Machine

- ^ Battie, 102-105: Le Corbellier, i-29

- ^ 'Science Of Early English Porcelain.' I.C. Freestone. Sixth Conference and Exhibition of the European Ceramic Club. Vol.ane Brighton, 20–24 June 1999, p.11-17

- ^ 'The Sites Of The Chelsea Porcelain Mill.' E.Adams. Ceramics (1), 55, 1986.

- ^ "Bow". Museum of London. Archived from the original on 3 December 2011. Retrieved 31 October 2011.

- ^ "Bow porcelain basin, painted by Thomas Craft". British Museum. Archived from the original on 4 Feb 2012. Retrieved 31 Oct 2011.

- ^ a b "Bow porcelain". British History Online. University of London & History of Parliament Trust. Archived from the original on 3 Dec 2011. Retrieved 31 October 2011.

- ^ "St James'due south (Charles Gouyn)". Museum of London. Archived from the original on iii December 2011. Retrieved 31 October 2011.

- ^ Ceramic Figureheads. Pt. iii. William Littler And The Origins Of Porcelain In Staffordshire. Cookson Mon. Bull. Ceram. Ind. (550), 1986.

- ^ "The History of Royal Crown Derby". Imperial Crown Derby. Retrieved 17 Dec 2020.

- ^ History of Royal Crown Derby Co Ltd, from "British Potters and Potteries Today", publ 1956

- ^ 'The Lowestoft Porcelain Manufacturing plant, and the Chinese Porcelain Made for the European Market during the Eighteenth Century.' L. Solon. The Burlington Mag. No. 6. Vol.II. August 1906.

- ^ "New American Standard Defines Polished Porcelain By The Porcelain Tile Certification Bureau." Tile Today No.56, 2007.

- ^ Porcelain tile as defined in ASTM C242 – 01(2007) Standard Terminology of Ceramic Whitewares and Related Products published by ASTM International.

- ^ 'Manufacturers Of Porcelain Tiles' Ceram.Earth Rev. 6, No.19, 1996 … 'The main manufacturers of porcelain tiles in Italian republic, Europe, Asia, Africa, Oceania and the Americas are listed.'

- ^ "Italian Porcelain Tile Production At The Top" Ind.Ceram. 27, No.2, 2007.

- ^ Porcelain Room, Aranjuez [ dead link ] Comprehensive only shaky video

- ^ a b "Porcelain Tile: The Revolution Is Simply Beginning." Tile Decorative Surf. 42, No.xi, 1992.

- ^ "What is a Bourdaloue?". wisegeek.com. 2014. Archived from the original on 13 December 2014. Retrieved 27 March 2014.

- ^ "Buick fabricated bathtubs before he congenital cars | Las Vegas Review-Journal". reviewjournal.com. 2014. Archived from the original on iv October 2014. Retrieved 27 March 2014.

- ^ "Maghsoud Factories Grouping". Maghsoud Factories Grouping. Archived from the original on 13 July 2016. Retrieved 26 July 2016.

- ^ "History". Zarin Iran Porcelain Industries. Zarin Iran Porcelain Industries. Archived from the original on 5 February 2017. Retrieved five Feb 2017.

- ^ "Trang chủ | Gốm sứ cao cấp Minh Long I". Archived from the original on 2017-02-23. Retrieved 2017-02-22 .

- ^ Richard Ginori: Gucci firma l'accordo per l'acquisizione | Il Sito di Firenze

- ^ Jiesia

- ^ Iwona Kienzler "Dwudziestolecie międzywojenne" Tom 48 "Kultowe marki" due south. 27 ISBN 978-83-7945-029-9

- ^ "Polskie Fabryki Porcelany 'Ćmielów' i 'Chodzież' S.A." Polskie Fabryki Porcelany Ćmielów i Chodziez S.A. Archived from the original on nineteen November 2016. Retrieved 31 January 2017.

- ^ "Kristoff Porcelain". Kristoff Porcelain. Archived from the original on 24 July 2016. Retrieved 26 July 2016.

- ^ "Lubiana Due south.A. - polski producent porcelany dla domu i rynku horeca". Lubiana Due south.A. - polski producent porcelany dla domu i rynku horeca. Archived from the original on ten December 2016. Retrieved 31 January 2017.

References [edit]

- Battie, David, ed., Sotheby's Curtailed Encyclopedia of Porcelain, 1990, Conran Octopus. ISBN 1850292515

- Le Corbellier, Clare, Eighteenth-century Italian porcelain, 1985, Metropolitan Museum of Art, (fully available online as PDF)

- Smith, Lawrence, Harris, Victor and Clark, Timothy, Japanese Art: Masterpieces in the British Museum, 1990, British Museum Publications, ISBN 0714114464

- Vainker, S.J., Chinese Pottery and Porcelain, 1991, British Museum Press, 9780714114705

- Watson, William ed., The Great Nihon Exhibition: Art of the Edo Period 1600–1868, 1981, Royal University of Arts/Weidenfeld & Nicolson

Further reading [edit]

- Burton, William (1906). Porcelain, Its Nature, Art and Manufacture. London: Batsford.

- Combined Nomenclature of the European Communities – EC Commission in Luxembourg, 1987.

- Finlay, Robert (2010). The Pilgrim Art: Cultures of Porcelain in World History. Vol. xi of California World History Library (Illustrated ed.). University of California Press. ISBN978-0-520-94538-eight . Retrieved 24 April 2014.

- Guy, John (1986). Guy, John (ed.). Oriental trade ceramics in South-East Asia, ninth to sixteenth centuries: with a catalogue of Chinese, Vietnamese and Thai wares in Australian collections (Illustrated, revised ed.). Oxford University Press. ISBN9780195825930 . Retrieved 24 April 2014.

- Rackham, Bernard. A Book of Porcelain at Project Gutenberg

- Valenstein, S. (1998). A Handbook of Chinese ceramics, Metropolitan Museum of Art, New York. ISBN 978-0-87099-514-9.

External links [edit]

| | Wikimedia Commons has media related to Porcelain. |

- How porcelain is made

- How bisque porcelain is fabricated

- ArtLex Art Lexicon – Porcelain

Source: https://en.wikipedia.org/wiki/Porcelain

0 Response to "What Substance Did Portuguese Explorers Refer to as White Gold? Art History"

Post a Comment